Blog

Introduction

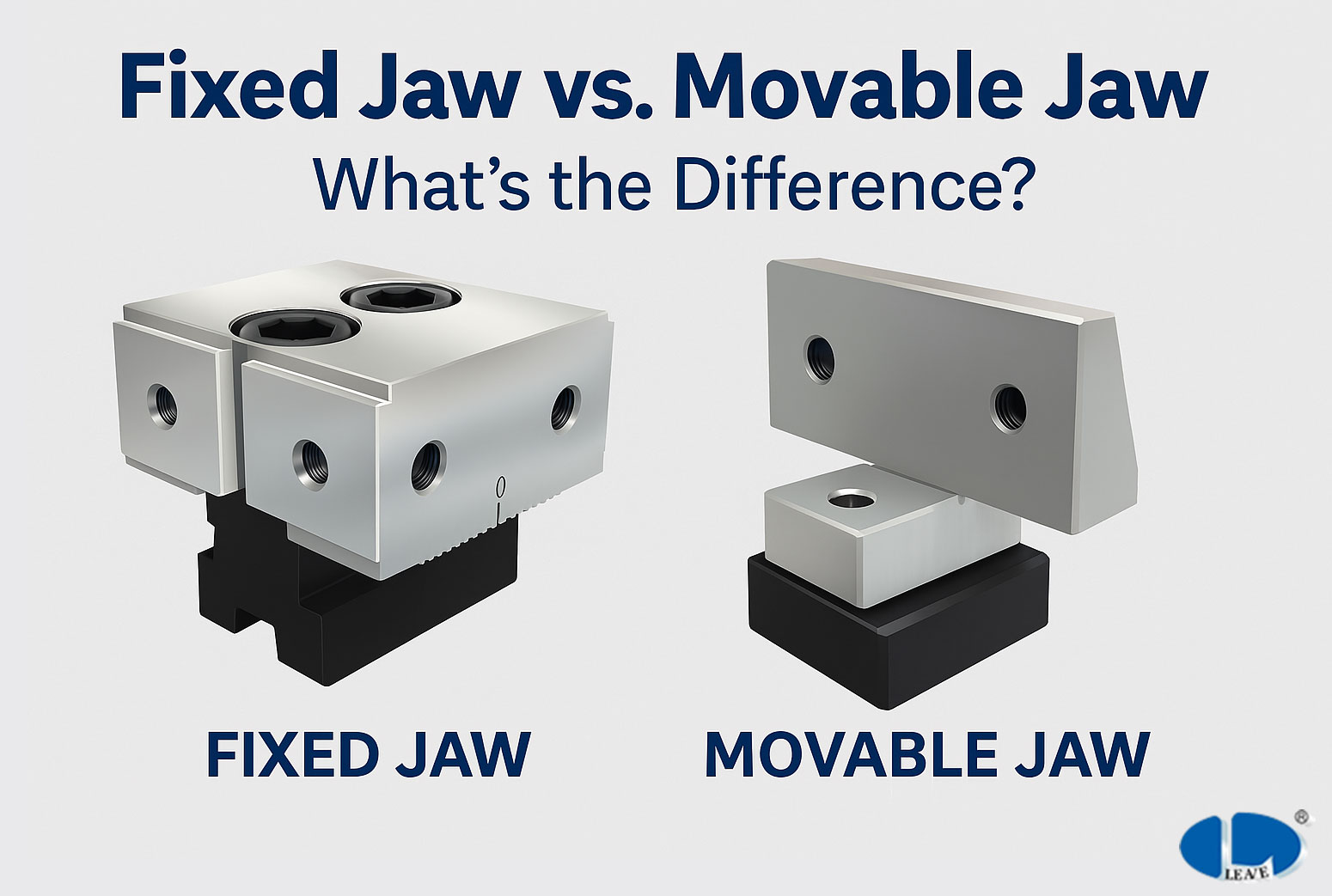

In precision machining and modular workholding systems, the choice of jaws plays a critical role in performance and accuracy. Two of the most common components are the fixed jaw and the movable jaw, and while they work together in most setups, each serves a distinct purpose. Understanding the differences between these jaws—and when to use each—can help machinists, engineers, and toolmakers improve efficiency and achieve consistent results.

At LEAVE, we often receive questions from users about which jaw type is best suited for specific machining needs. This article is designed to clarify the key differences between fixed jaws and movable jaws, and help you decide how to best use each one in your workholding system for optimal performance.

What Is a Fixed Jaw?

A fixed jaw is the stationary part of a vise or clamping fixture. It does not move and serves as the primary reference point for aligning and securing the workpiece. Fixed jaws are typically mounted directly to the base of the vise or fixture plate and are designed to withstand consistent clamping pressure without shifting.

Key Features of Fixed Jaws:

- Provides a stable, unmovable clamping point

- Often made from hardened steel or durable alloys

- Can include step, serrated, or soft jaw types for specific workpieces

- Used as the reference side in setup and alignment

What Is a Movable Jaw?

A movable jaw, as the name suggests, is the adjustable component of the vise. It slides along guideways or is driven by a lead screw or hydraulic system to clamp the workpiece against the fixed jaw. This part is responsible for applying pressure and accommodating workpieces of varying sizes.

Key Features of Movable Jaws:

- Allows for adjustable clamping range

- Works in conjunction with the fixed jaw to hold the workpiece

- Can also be customized with different jaw faces

- Operated manually, mechanically, or hydraulically

Fixed Jaw vs. Movable Jaw: Key Differences

| Feature | Fixed Jaw | Movable Jaw |

| Movement | Stationary | Adjustable/Sliding |

| Function | Acts as reference and support | Applies clamping pressure |

| Installation | Bolted or integrated into the base | Slides along vise body or guideway |

| Use Case | Essential for precision alignment | Provides flexibility in clamping |

When to Use Each Jaw Type

Use Fixed Jaws When:

- You need a reliable reference surface for repeatable setups

- Stability and rigidity are top priorities

- You're working with modular vise systems or fixture plates

- High-precision applications require minimal movement or vibration

Use Movable Jaws When:

- You require flexibility to clamp parts of different sizes

- Adjustability and quick setup changes are needed

- You're working with complex or asymmetrical workpieces

- You want to apply consistent clamping pressure with minimal effort

In most setups, fixed and movable jaws are used together. However, understanding when and how to choose the right type of fixed jaw—such as step jaws, serrated jaws, or soft jaws—can significantly impact the success of your machining operations.

Explore LEAVE's Jaw Solutions

LEAVE not only offers a wide range of fixed jaws but also provides various movable jaw options to support diverse modular vise configurations. Whether you need heavy-duty support for stable referencing or adjustable clamping for flexible setups, LEAVE's SVF Series includes precision-engineered jaw components built for durability, accuracy, and high-performance machining.

From step jaws to serrated and standard types, both fixed and movable jaws are available in multiple configurations to suit different workpiece sizes, shapes, and processing needs. Explore the full lineup on our SVF Series product page to find the ideal combination for your modular vise system.

Conclusion

Choosing between a fixed jaw and a movable jaw isn't about selecting one over the other—it's about understanding how they complement each other in your clamping system. The fixed jaw provides the foundation for alignment and repeatability, while the movable jaw offers adjustability and clamping force for a wide range of workpieces.

Looking to upgrade your workholding setup with durable and precise jaw components? Contact LEAVE today to discover high-quality solutions tailored to your machining needs.